Ensuring the safe operation of nuclear power plants is of utmost importance. In a nuclear power plant, welded plate structures act as gas-tight barriers to prevent the release of radioactive particles. An important issue is how to detect corrosion in the containment liners in the reactor containment buildings. The containment liners are often embedded in thick concrete walls of the reactor containments. They are therefore difficult to inspect, and corrosion can jeopardise their leak tightness long before visible damage occurs. Early detection of corrosion is important as it is crucial for planning preventive measures.

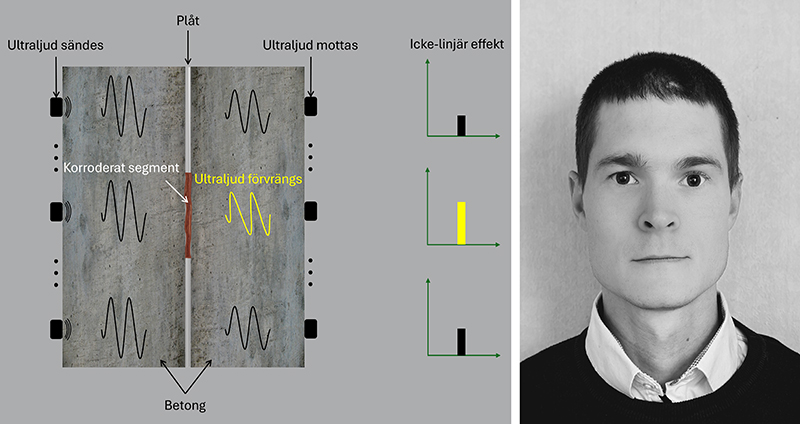

Markus Nilsson's thesis evaluates non-linear ultrasonic methods for detecting and evaluating corrosion in concrete-embedded containment liners. Ultrasonic testing uses sound waves above the human audible range to image internal structures. However, in concrete, high-frequency sound waves are effectively attenuated, requiring the use of relatively low-frequency ultrasound. This limits the resolution and makes it more difficult to detect small defects.

In his research, Markus Nilsson has found that non-linear ultrasound can be used to find defects in steel plates embedded in concrete:

- ‘With non-linear ultrasound, you look at how the signal changes in frequency and content. Non-linear ultrasound is extremely sensitive to very small defects. This means that relatively low-frequency ultrasound can be used to penetrate deep into a structure and still detect small defects.

The biggest challenge is that concrete naturally contains many defects. There are microcracks from when the concrete dries, there are small voids and a heterogeneous composition of different materials,’ explains Markus Nilsson:

- ‘This makes the analysis more complex, but the results show that it is possible to localise and evaluate corrosion in steel plates embedded in concrete using the non-linear ultrasound. In addition, the methods show potential for detecting embedded foreign objects, such as wood, and separations between the plate and the concrete.

How It Works: Ultrasound is transmitted from the surface of the concrete and travels through the material toward an embedded steel plate. In sections where the plate is free from corrosion, the signal undergoes only attenuation and exhibits weak nonlinearity. In corroded areas, both attenuation and nonlinear response increase significantly due to cracks in the rust and concrete. This is visible in the waveform, which changes as new spectral components are generated. Non-linear effects are analyzed by measuring the strength of these new frequencies in relation to the fundamental frequency. By combining information on both attenuation and nonlinear response, corrosion damage can be classified more precisely.

– To be completely honest, when I started this project, I thought this was impossible, far too difficult. But it turned out really well!

Is anyone currently using this method to inspect nuclear power plants?

– There is a company in Sweden that works with this type of testing, but primarily on steel components, not concrete structures. As of today, no one is conducting this kind of testing on nuclear power plants, but with a lifespan of up to 80 years, it is more important than ever to be able to assess the condition of concrete structures. Non-linear ultrasound may become a valuable complement to conventional testing techniques. To gain a more comprehensive understanding of a structure’s condition, it is crucial to combine multiple methods based on different physical phenomena.

– Continuous monitoring is also becoming increasingly important to track changes over time and account for seasonal variations. It is also essential to focus on which methods are most relevant for evaluating nuclear power plant structures, even when constructing new facilities. Operational safety is key!

More experiments are needed to evaluate the method further.

– We need to conduct additional experiments with more realistic specimens to fully evaluate the detection capability and applicability of the methods. These experiments should consider challenges posed by natural microcracks in concrete, coarse aggregates, dense reinforcement, and the large dimensions typical of actual nuclear power plants.

Markus Nilsson has received funding for the second phase of this project. There is an ambition to create a mock-up that will resemble a small section of a reactor building.

– I’ve been given the fantastic opportunity to continue as a postdoctoral researcher at the Division of Engineering Geology at Lund University! It will be incredibly exciting to continue working on this challenge. Nuclear power plays a major role in the energy transition, and it feels great to be part of developing methods that enhance its operational safety.